Tank ammunition

Contents

Ammunition shell types

Tank shells come in two general categories: Kinetic energy shells, and chemical energy shells.

Kinetic energy shells' ability to penetrate, and depending on the type of shell, also to do damage, depends on a combination of the shell's mass, speed, and hardness. Since mass and hardness are constant for a shell, this means that the longer a shell flies, the more speed it loses due to air resistance and the less damage it will cause.

Chemical energy shells do their damage based on a chemical reaction, and unlike kinetic shells, their ability to penetrate and do damage are not affected by the shell's speed. This means that they do the same amount of damage regardless of the distance to the target if they hit.

It can be worth noting that there is no '-T'-suffix to tank shells. It is assumed that all tank shells have a tracer component in the shell base.

Kinetic energy shells

- Armor Piercing (AP)

Basic solid steel shot, which uses kinetic energy to defeat the armour plate. The shot causes damage by fully or partially penetrating the armour plate, causing steel fragments of the shot and the armour plate to hit crew members, automotive components, ammunition, fuel tanks, etc. The standard early-World War II ammunition for most nations.

- Armor Piercing, Capped (APC)

Here a nose cone (or cap) of softer metal was fixed to the front of the solid shot. When this struck the target armour the shock was transferred away from the tip of the round to the neck, thus helping prevent shatter. An added bonus was that it was found that the softer caps improved "grip" against sloped armour, squashing on impact to allow the main shot to penetrate rather than glancing off. A downside with the cap was the decrease in long-range accuracy due to the cap interfering with the shell's aerodynamics.

- Armor Piercing, Ballistic Cap (APBC)

To improve the aerodynamics of the AP shells, a ballistic cap can be added to the tip of the shot. This cap gives the shell a more pointed shape, allowing it to flow in the air more readily than a normal round. The cap is made of a brittle metal, which breaks on impact, and does not aid penetration nor give any slope "grip" as an APC round does.

- Armor Piercing, Capped, Ballistic Cap (APCBC)

A combination of the ballistic cap of APBC and the cap of APC, giving the round improved long-range accuracy and the slope grip. Note that some APCBC ammunition was only listed as APC and that APCBC shells can come both with and without a high explosive filler.

AP shots are often just solid metal shells that penetrate armour and causes damage by tearing through the interior and releasing shrapnel via spalling. The lethality of AP, APBC, APC, and APCBC shots can be increased by adding an explosive filler into the shell, intended to explode upon penetrating the enemy armour. This filler will, however, also decrease the mass of the shot, decreasing its ability to defeat the armour plate. In APCBC shell designations, the HE part is often just dropped e.g. the German Pz.Gr.39 round is "APHECBC" but is simply listed as an "APCBC". In-game, the images of each round and stat cards give a good indication on which shells have or don't have the explosive filler.

- Armor Piercing, Composite, Rigid (APCR) or High Velocity, Armor Piercing (HVAP)

A very dense core, usually made from tungsten carbide, in a soft metal shell. Upon impact, the soft shell will deform, causing the core to penetrate the armour plate at very high speeds. Compared to solid shot AP they create much less shrapnel so sniping for weak points is necessary. These shells were the primary high-velocity penetrator used during World War 2 before the transition to APDS rounds.

- Armor Piercing, Discarding Sabot (APDS)

Similar to the APCR in principle. Rather than a softshell, however, the thin, long shot discards it shell (sabot) upon leaving the gun barrel, reducing the shell's drag and thus reducing the loss of speed over distance, while not causing significant change to the mass of the penetrator compared to APCR. Compared to solid shot AP they create much less shrapnel so sniping for weak points is necessary. Most APDS penetrator rods were made from tungsten carbide, the same material for APCR, though some of the more modern ones still around use depleted-uranium instead for the penetrator.

- Armor Piercing, Discarding Sabot, Fin-Stabilized (APDS-FS)

Essentially an APDS round, with the exception of the shot having fins attached to stabilize its flight path. These are the most modern type of kinetic penetrator still in use today, with a majority of the battle-use rounds today made of depleted uranium, though there are still some that are made of tungsten carbide. These also generate far more spalling than standard APDS due to the longer penetrator,

Chemical energy shells

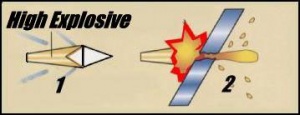

- High Explosive (HE)

While originally meant as an anti-infantry measure and not intended to destroy tanks, high explosive rounds can damage tanks by destroying their tracks or damaging periscopes and automotive parts, and even crack and destroy armour plates if sufficiently powerful. Probably the main exponents of this approach were the Soviets, who not only issued every gun with some form of an anti tank round, they were also happy to shoot HE at tanks. A 152 mm HE shell will spoil anyone's day.

- High Explosive Squash Head (HESH)

A thin-walled shell filled with a plastic explosive that upon impact causes the explosive to "pancake" onto the armour, which a fraction of a second later is detonated by a charge in the shell. The explosion will cause a shockwave in the armour and knock loose metal fragments on the other side of the armour (spalling), showering the inside of the tank with them. It has the best effect against flat armour surfaces, and relatively thick armour since thin armour does not cause sufficient spalling. This shell type appeared after WW2 and was mainly used by the British.

In game it ignores any armour-angle, except for ricochets, and deals damage by metal-flakes which are blown off inside the armour by the exterior explosion. In short, the fighting compartment is showered in metal rain. Currently, only true armour thickness (opposed to a line of sight thickness, again armour-angles are ignored) will provide sufficient means of protection.

- High Explosive, Anti-tank (HEAT)

Rather than relying on penetration by pure kinetic energy, the HEAT shell achieves penetration through a combination of chemical and kinetic energy. When a HEAT shell detonates on impact, a metal cone (often copper) is cold-formed by the pressure created by the detonation of the HE-charges surrounding it, turning the metal cone into a metal beam which penetrates armour at supersonic speeds. Thanks to the HE-charge creating the penetration potential on impact unlike conventional kinetic rounds, HEAT rounds do not lose any penetration potential even on very long distances. Another advantage of a HEAT round is its multi-purpose damage characteristics; the explosion by the HE-charge makes HEAT also effective against soft targets like trucks. Facing armour, the metal beam creates on penetration a deadly cone of armour fragments, destroying any modules or crew members in its way, though in-game the after penetration damage can be quite annoyingly punctual requiring a very precise aim. This ammo type was greatly improved past the sixties to improve on many issues the first WW2 iterations had like limited after penetration effects, low travelling speeds and penetration.

- High Explosive, Anti-Tank, Fin-Stabilized (HEAT-FS)

A more sophisticated form of the HEAT round above. The HEAT-FS round has an advantage over HEAT by having a higher muzzle velocity as well as a more lethal warhead. A HEAT-FS round can penetrate an average of 300 mm of armour at any range, making them a very good round to use on long-range target as well as close-range. This is often the stock round of some MBTs.

- Anti-Tank Guided Missile (ATGM)

Main article: Anti-tank Guided Missile

This is a HEAT-FS round with a twist. Instead of being sent to its target via a straight trajectory, the HEAT warhead is guided by a missile projectile, controllable by the player. This allows far-range target that had to be manually ranged by distance to be targeted with pinpoint accuracy with a missile that can change direction by command. Though a general disadvantage is the large missile size that restricts ammo count, the lethality given by this option allows players to seek out and destroy enemies at distances they would not even think of being engaged at. Despite a long effective range, ATGMs have a much slower velocity than standard anti-tank ammunition.

- Smoke

Main article: Smoke

A specialized shell that causes no noticeable damage to an armoured vehicle, but it allows the player to create their own smoke screen to conceal a friendly position from enemy fire. Smoke lasts between 20-30 seconds and it obscures line-of-sight vision and also hides markers from friendlies and enemies. A noticeable trait in all smoke shells in comparison with regular shells is the reduced muzzle velocity due to most of the shell being taken up by smoke-generating material, rather than charge.

Ammo Racks

Ammunition for ground vehicles is stored in Ammo racks.